We are constantly improving our installations through collaboration and exchange within our company and with our customers. In addition, we actively participate in Flemish research programmes, including development and demonstration projects, with numerous knowledge and industrial partners.

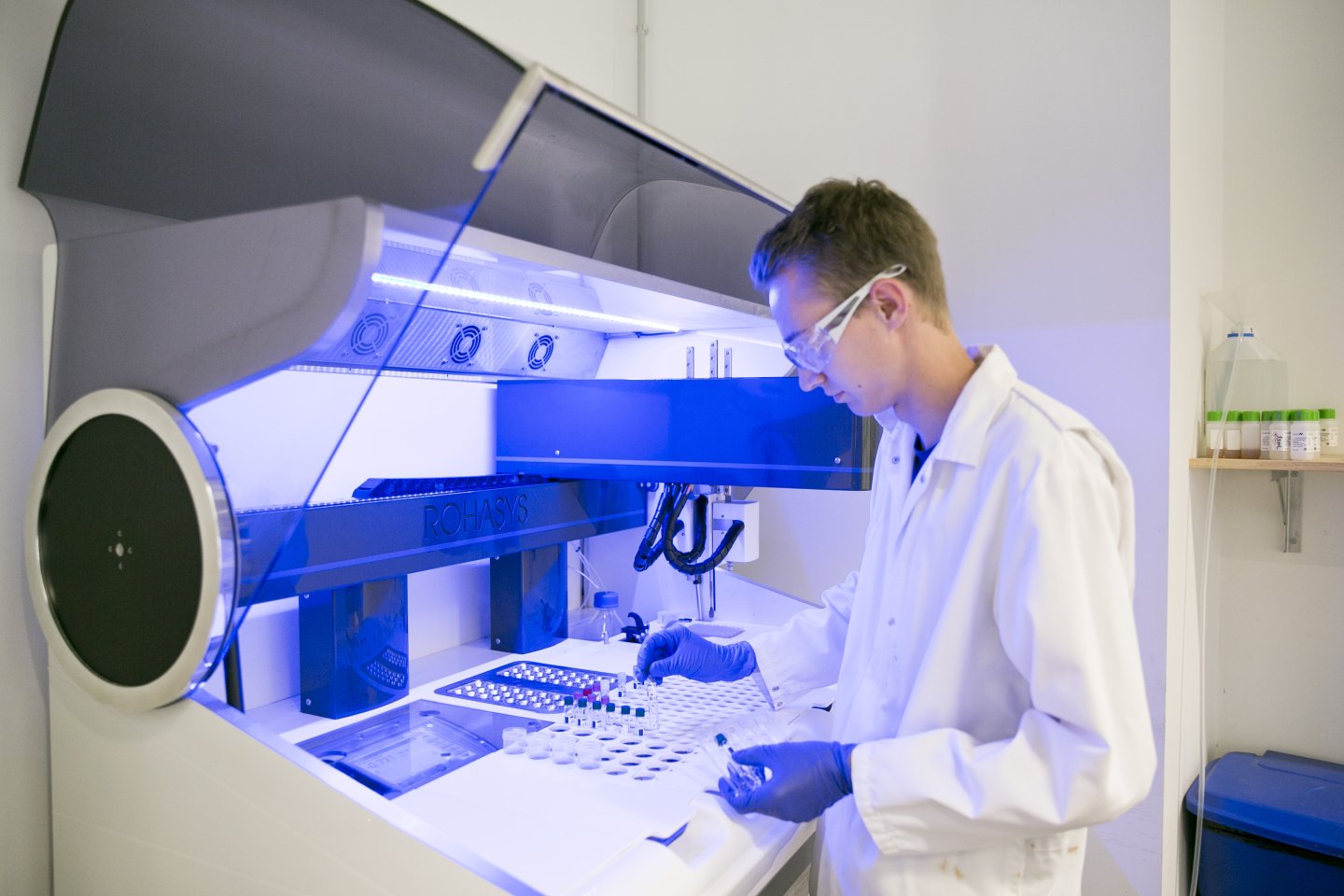

Pilot testing

If you are considering a large project, it may be useful to include a test phase first. We will construct a pilot installation to carry out all the necessary tests.

Micropolar

Duration: 11/01/2023 - 11/01/2025

Partners: ACK, Van Ganzenwinkel

With the support of: VLAIO

Since 2022, micropollutant removal has once again found itself high on the agenda. This is a complex issue, because most compounds are non-biodegradable and cannot be measured. Furthermore, they require high analysis costs and are subject to very strict standards. At the same time, few affordable and reliable techniques to remove micropollutants exist on the market.

Pantarein Water is currently putting maximum effort into the development of a decision tree that, depending on the micropollutants present, helps us to determine the optimal combination of technologies. To that effect, we use filtration and adsorption techniques.

WaterLOOP

Duration: 01/01/2022 – 01/01/2026

Partners: Brouwerij Huyghe

With the support of: VLAIO

Furthermore, wastewater carries extremely valuable information. From production losses and water consumption to heat efficiency and consumption of chemicals: All of this can be deduced from water analysis.

On this premise, the digital platform WaterLOOP was developed: this connects the water-related processes from production with the smart monitoring of water treatment and water management. The aim: to provide more sustainable and stable treatment on the one hand, while generating feedback for the production environment to optimize the processes on the other. This leads to a decrease in consumption of water, raw materials, chemicals,

eAutomate

Duration: 09/2020 – 09/2022

Partners: BIOMATH (Ghent University), Boortmalt, Huyghe brewery

With the support of: VLAIO

Pantarein and the BIOMATH research group work together to run the water treatment plants at Boortmalt and Hughe brewery in a more intelligent way. With this project, we make digitalization tangible. We are building up advanced process knowledge, which we apply via a mathematical model to develop an automatic and cost-efficient arrangement that benefits both the customer and the operator.

RepEAT: closing the loop in the food industry

Duration: 01/2020 – 03/2022

Partners: Flanders’ FOOD, Citrique Belge, Brouwerij Haacht, Volys

With the support of: VLAIO

Using pilot tests, we investigated pre-treatment techniques that can increase the efficiency of water treatment and reduce operational costs. We compared two reuse technologies: ultrafiltration/reverse osmosis and membrane bioreactor /reverse osmosis. In addition, innovative technologies for quality assurance were also tested. The results show it is also possible for food companies to reuse purified process water – where the process water must meet high quality requirements.

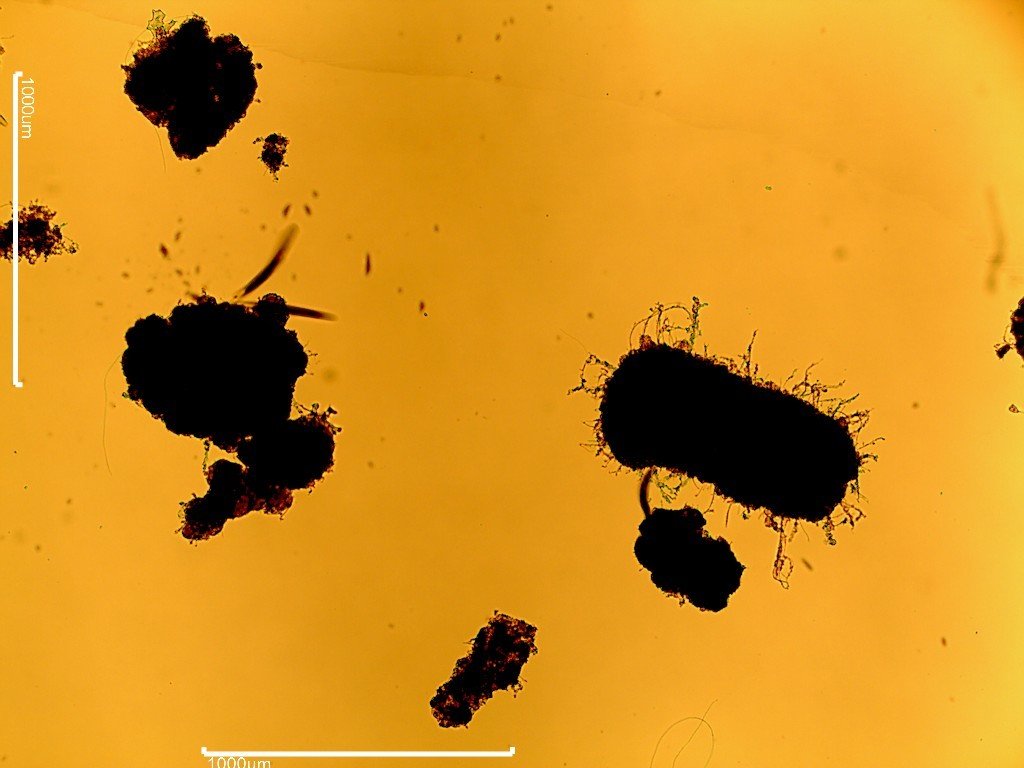

AEROGRAM: aerobic granular sludge for membrane filtration

Duration: 01/2019 - 06/2020

Partners: BioWAVE (University of Antwerp), VITO, Izico, WZI Olen

With the support of: Vlakwa

In the AEROGRAM project, we demonstrated that the aerobic granular sludge technology can also be implemented in industrial wastewater - in this case largely from meat processing companies. We showed that it is possible to form sludge with excellent settling properties via appropriate process control, and that a good sludge structure increases the efficiency of an MBR installation and thus facilitates water reuse.

CARVE: chemical-free wastewater recovery in the food industry

Duration: 01/2017 - 12/2017

Partners: VITO, Allgro, Paas Food, Wateris, Fevia

With the support of: Vlakwa

In the CARVE project, we conducted a pilot study with a membrane bioreactor (MBR) and reverse osmosis (RO) on the sites of the end users Allgro and Paas Food. In addition, we studied an alternative technique for the reduction of biofouling and evaluated the preconditions for water reuse. This project showed that an MBR+RO produces water of process water quality. We achieved a maximum reuse efficiency. Furthermore, we developed a guideline for reuse in the food industry.

DUWAHE2: wastewater reuse and heat recovery for small breweries

Duration: 01/2015 - 12/2015

Partners: VITO, Huyghe brewery, Bosteels brewery, CORE

With the support of: Vlakwa

Together with research partner VITO and student cooperative CORE we wanted to demonstrate that reuse of treated wastewater and heat recovery from a water treatment plant are affordable, also for smaller breweries. By implementing an RO installation, the water consumption of the Huyghe brewery dropped to 3 litres of water per litre beer. In addition, it proved possible to recover heat from the biological treatment system of Bosteels via a double heat exchanger.

Contact us!

Would you like to bring in our expertise in a research programme? Get in touch with our innovation department!