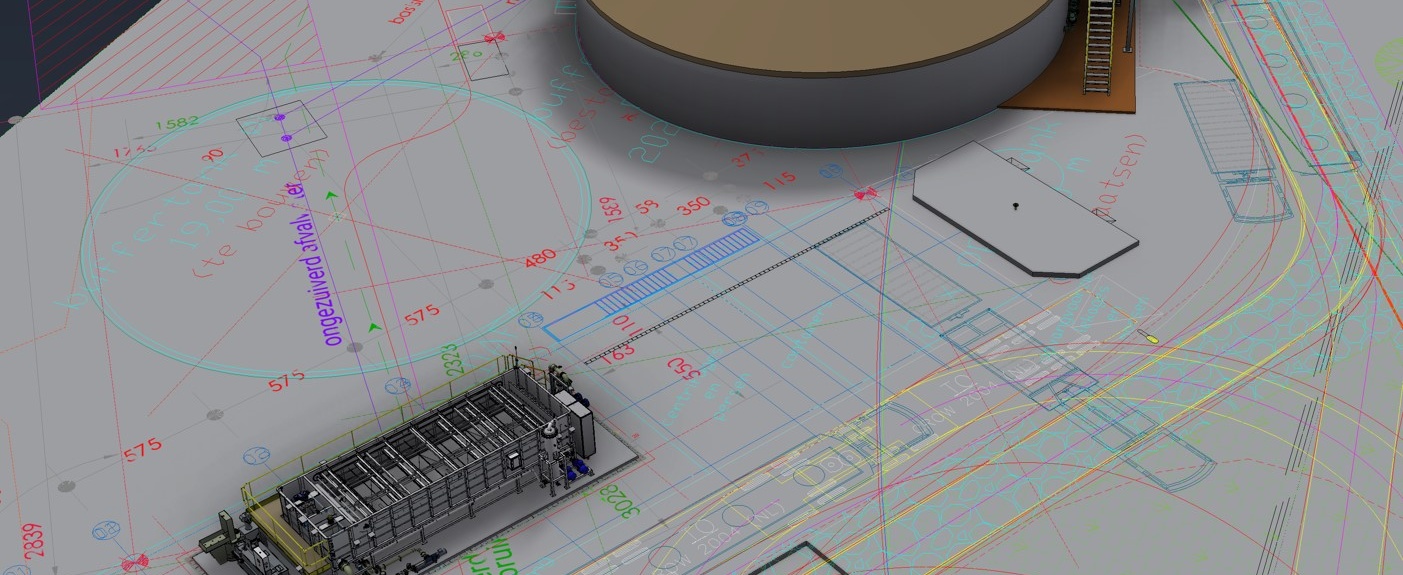

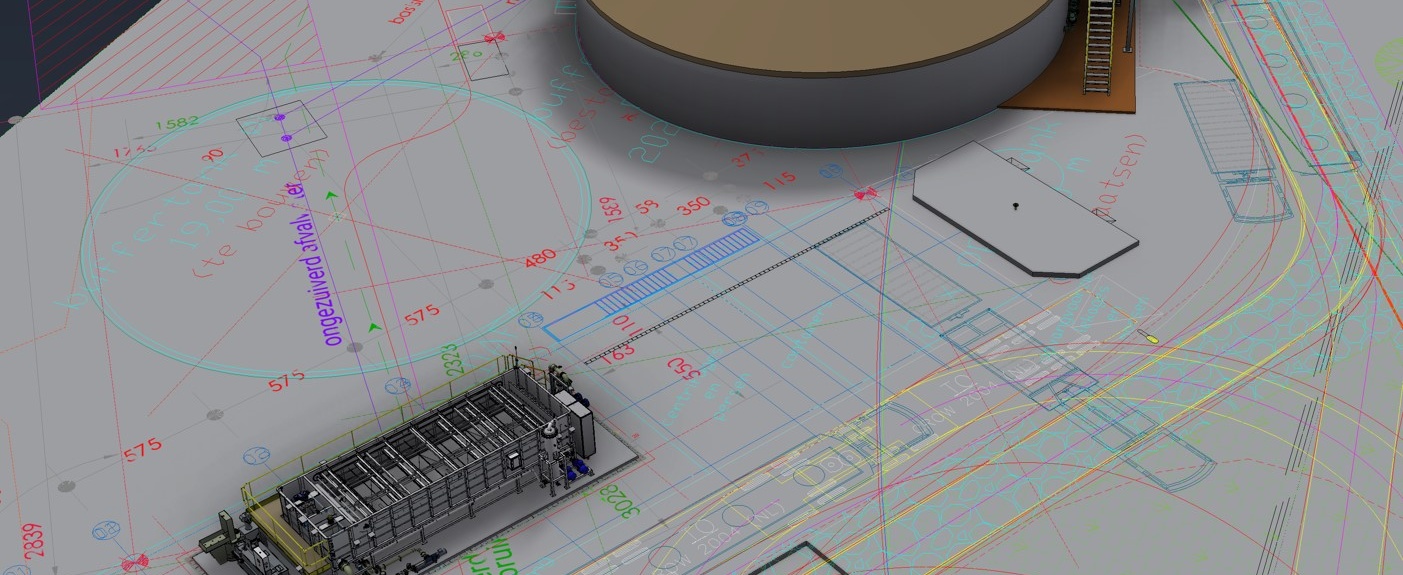

Inex is a proud Belgian dairy producer located in Sint-Lievens-Houtem. To meet the stricter discharge standards, as well as to prepare for a shortage of groundwater and drinking water of sufficient quality, Pantarein Water developed a master plan for the company, to be implemented in phases.

In the first phase, a calamity tank was built to relieve the existing treatment plant. The second phase entails building a pre-treatment unit. With minimal consumption of chemicals, it will still convert 25% of the load into an energy-rich sludge. That sludge will subsequently be converted into biogas by third parties located in the immediate vicinity. A third phase involves installing membrane filtration technologies that will produce up to 800 m³ of drinking water per day, which will reduce the company’s water consumption and offer a solution to its water worries. These plants will be in use by the end of 2024.